Current location:

Links:

-

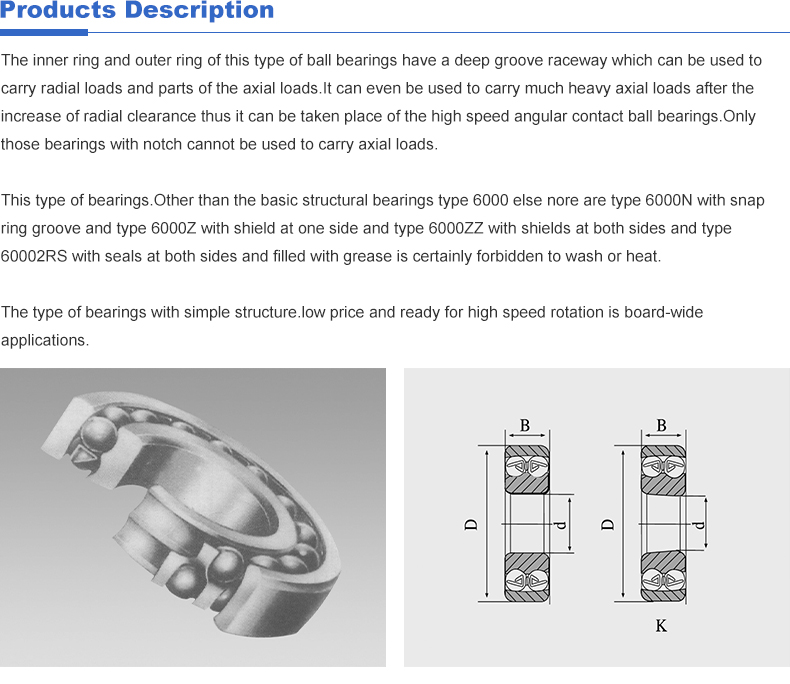

| Width (B) | 15 | The width of the bearing, perpendicular to the axis. | The Significance of the 62207 Bearing in Modern Machinery The term inch in the name refers to the bearing's dimensions being measured in inches rather than metric units. This is important because it indicates the bearing's compatibility with machinery designed for the imperial measurement system. Inch tapered roller bearings come in various sizes and configurations, including single row, double row, and four-row versions, each offering different levels of capacity and performance. The Enigmatic Nature of 6206 zz Maintenance Tips for Bearing 32211 The AN2002 Series Single-Row Deep Groove Ball Bearings A Comprehensive Guide Fafnir angular contact ball bearings are also known for their durability and reliability Conclusion * Bore diameter The diameter of the inner raceway Material composition, often a combination of high-quality steel and lubricants, plays a significant role in the bearing's resistance to wear, corrosion, and temperature extremes. The size chart might also provide information on additional features, such as seals or shields, that protect against contamination and improve lubrication retention. The price of a 30209 bearing is an important factor to consider when purchasing industrial equipment or machinery. This type of bearing is commonly used in various applications such as automotive, agriculture, and construction. In the world of mechanics, the introduction of the 6308 z bearing has been a game-changer, offering unparalleled efficiency and durability for rotary systems. This innovative component is designed to withstand heavy loads and high speeds, making it an essential part in various industries ranging from automotive to aerospace. Conclusion Sealed Tapered Roller Bearings The Ultimate Solution for High Load Capacity and Efficiency

One of the key advantages of these bearings is their ability to accommodate misalignment to a certain extent. However, proper installation and maintenance are vital to ensure optimal performance and prevent premature failure. Regular lubrication, cleaning, and inspection can significantly enhance the bearing's lifespan. One of the key advantages of the 23944 bearing is its ability to operate at high speeds while maintaining low friction and noise levels. This makes it suitable for a wide range of machinery and equipment, including pumps, gearboxes, and conveyors. Its versatile design also allows for easy installation and maintenance, reducing downtime and ensuring efficient operation. Proper maintenance is essential for ensuring the longevity and optimal performance of Bearing 51309 In the realm of mechanical engineering, bearings play a pivotal role in ensuring smooth and efficient operation of machinery. One such critical component is the NU 209 bearing, a specific type of cylindrical roller bearing that has made significant contributions to various industries. Introduction Another benefit is their adaptability to shaft misalignment

One of the key advantages of the LM67010 bearing is its ability to accommodate misalignment. This feature is particularly useful in situations where the shaft or housing may experience some degree of misalignment, as it ensures that the bearing can still operate smoothly without compromising its performance. This level of adaptability makes the LM67010 a versatile option for a wide range of industrial applications. The most common types of double row deep groove ball bearings are Bearings are fundamental components in various mechanical systems, playing a crucial role in reducing friction and enabling smooth motion. Over the centuries, bearings have undergone significant advancements, driven by technological innovations and evolving industrial needs. This article explores the evolution of bearings, from their origins to the advanced designs of today. * Aerospace These bearings are used in aircraft engines, landing gear systems, and other critical aerospace components to ensure reliable performance under extreme conditions.

One of the key advantages of the LM67010 bearing is its ability to accommodate misalignment. This feature is particularly useful in situations where the shaft or housing may experience some degree of misalignment, as it ensures that the bearing can still operate smoothly without compromising its performance. This level of adaptability makes the LM67010 a versatile option for a wide range of industrial applications. The most common types of double row deep groove ball bearings are Bearings are fundamental components in various mechanical systems, playing a crucial role in reducing friction and enabling smooth motion. Over the centuries, bearings have undergone significant advancements, driven by technological innovations and evolving industrial needs. This article explores the evolution of bearings, from their origins to the advanced designs of today. * Aerospace These bearings are used in aircraft engines, landing gear systems, and other critical aerospace components to ensure reliable performance under extreme conditions.  Precision Manufacturing This bearing is manufactured with precision tolerances, ensuring accurate alignment and smooth rotation Precision Manufacturing This bearing is manufactured with precision tolerances, ensuring accurate alignment and smooth rotation

Precision Manufacturing This bearing is manufactured with precision tolerances, ensuring accurate alignment and smooth rotation Precision Manufacturing This bearing is manufactured with precision tolerances, ensuring accurate alignment and smooth rotation ball bearing 6004 2rs. The bearings are also subjected to strict quality control checks to ensure consistent performance. The 22211K bearing is a high-quality bearing that is commonly used in various industries for a wide range of applications. This bearing is designed to withstand heavy radial and axial loads, making it ideal for use in heavy machinery and equipment.

ball bearing 6004 2rs. The bearings are also subjected to strict quality control checks to ensure consistent performance. The 22211K bearing is a high-quality bearing that is commonly used in various industries for a wide range of applications. This bearing is designed to withstand heavy radial and axial loads, making it ideal for use in heavy machinery and equipment. Inner Diameter (ID) Cylindrical roller bearings, an essential component in various mechanical and engineering applications, play a crucial role in facilitating smooth and efficient rotation while supporting heavy loads. These bearings, with their unique design featuring cylindrical rollers, offer high radial load capacity and excellent rigidity, making them indispensable in industries ranging from automotive to aerospace. 2. Precision Manufacturing The bearing is manufactured using advanced techniques, ensuring that it meets the highest standards of precision and quality. The Unparalleled Performance of 6004 Ball Bearings

Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions

Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions Moreover, the self-aligning feature of these bearings enables them to accommodate misalignments, making them versatile and adaptable to different operating conditions 32238 bearing. Design and Functionality A 606ZZ bearing is a common type of miniature ball bearing that finds application in various machinery and equipment due to its compact size, high load capacity, and smooth operation. The dimensions of this bearing play a crucial role in determining its compatibility and efficiency in different mechanical systems.

32238 bearing. Design and Functionality A 606ZZ bearing is a common type of miniature ball bearing that finds application in various machinery and equipment due to its compact size, high load capacity, and smooth operation. The dimensions of this bearing play a crucial role in determining its compatibility and efficiency in different mechanical systems. 4. Precision Alignment The bearing's precision alignment capabilities ensure smooth operation and reduce wear and tear on other components. This feature is particularly beneficial in applications where accurate positioning is essential, such as robotics and automation systems. * Outer diameter The diameter of the outer raceway.

In summary, the key difference between spherical roller bearings and cylindrical roller bearings lies in their design, load-carrying capabilities, and suitability for specific applications. Each type of bearing is tailored to meet distinct operational requirements and environmental conditions in diverse industrial applications.

* Cleaning the bearing and surrounding area to remove dirt and debris On the other hand, the increased cost of bearings can also be passed down to consumers through higher equipment prices 32312 bearing price. This can limit the adoption of new machinery and technologies, particularly in sectors where affordability is a key consideration. As a result, the industry may struggle to keep pace with technological advancements and remain competitive in the global market. * Taper angle 112 The environmental impact of Bearing 32010X is also noteworthy

32312 bearing price. This can limit the adoption of new machinery and technologies, particularly in sectors where affordability is a key consideration. As a result, the industry may struggle to keep pace with technological advancements and remain competitive in the global market. * Taper angle 112 The environmental impact of Bearing 32010X is also noteworthy